What is the best Greenteeth set up for my machine?

This is an easy one. Please click here to launch to our Machine Setups pages where you will find the make and model of your machine. All the info you need is clearly detailed. If you cannot find your machine, or have any questions, please call us on 1800-681733.

How do I sharpen my Greenteeth?

There are two methods to shapen the teeth - click the "Sharpening" menu above for all the info. If you have any questions about the process, please call us on 1800-681733

Deep Dish tooth - Standard Dish tooth - What's the difference?

The Deep Dish teeth are a deeper dished tooth designed to be the general all-around best tooth for Australian and New Zealand conditions. They offer a tremendous sheering action and a very smooth cut. They carry an edge very well and using them can be like adding horsepower to your machine. If you think you will encounter a fair amount of rock in your stump grinding then do not use the deep dish teeth. Go for the standard dish teeth. The Deep Dish teeth are a deeper dished tooth designed to be the general all-around best tooth for Australian and New Zealand conditions. They offer a tremendous sheering action and a very smooth cut. They carry an edge very well and using them can be like adding horsepower to your machine. If you think you will encounter a fair amount of rock in your stump grinding then do not use the deep dish teeth. Go for the standard dish teeth.

The Standard Dish teeth excel in rocky soil. They take a shock very well. The dish, or concave, is similar to the angle found on standard 1/2" shank teeth. The only difference between the Standard Dish and Deep Dish is the angle of the carbide. The grade of the carbide, the way they're made, and materials they are made with are all the same, as is the price.

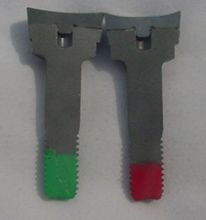

Every series of Greenteeth® has its own Standard Dish and Deep Dish style tooth. The Standard Dish is shown with the green thread in the photo below, and the Deep Dish is shown with the red thread.

What should I torque my pocket bolts to?

Both the GBLP Series of Lo-Pro™ bolts and GreenBolt® and Allen Head Cap Screw should be torqued to 180 Foot Pounds = 244 Newton Metres.

DO NOT over-torque the bolts! Over-torqueing the bolts will cause them to stretch. If you do over-torque a bolt, discard it. Torque them again after 10 hours of use, and then again after every day's work for the first 2-4 days after installing the pockets. This ensures that the bolts become securely seated.

What should I torque my teeth to that require a nut to hold it to the pocket?

Insert the tooth, carbide facing down, through the bore of the pocket. The shoulder on the tooth should seat on the detent in the pocket. Install the nut and torque to the Series specifications below.

- 700 Series - 20 to 28 Foot Pounds = 27 to 38 Newton Metres

- 900 Series - 31 to 43 Foot Pounds = 42 to 58 Newton Metres

- 1100 Series - 45 to 62 Foot Pounds = 61 to 84 Newton Metres

Once you have the feel for the proper tightness of the nut, with care you can use an open-end or a box wrench in the field to remove or rotate your teeth.

Getting the most life out of your Greenteeth®

Although GREENTEETH® are designed to handle the harshest work conditions, keep this fact in mind: For every (1) second your teeth are in concrete or stone compares equally to holding your tooth on a green wheel for 10 seconds. Carbide, regardless of manufacturer, wears down much faster in rocky soil. Use good sense and remove hazards when possible.

When grinding in known rocky soil, the GREENTEETH® system offers a good alternative to exposing your sharp cutter teeth to inevitable damage. Simply replace your outermost cutters with used dull teeth. As your carbide tip becomes rounded (dull) its impact resistance actually increases greatly, making "dull" teeth the perfect tool for rocky conditions. Then swap your innermost teeth with the outers and you are quickly back to grinding at maximum efficiency.

Thank you for purchasing GREENTEETH®. We sincerely believe you have purchased the best stump cutting teeth available. However, we are continuously working to improve our products as well as develop new ones. Your feedback is important and we encourage you to use our toll free number for any questions or comments you may have concerning your GREENTEETH® tooth and pocket system. |